|

|

Virtual

Light Meter

While it is important to be able to accurately depict

the full BRDF of a material, there is also much merit in the ability

to characterize a material with appearance attributes such as glossiness

or haziness. To this end, people in the appearance industry have sought

to develop and standardize a number of simple measurements and corresponding

measuring devices which easily and objectively quantify the reflection

properties of a surface. The result is a number of one-dimensional

scales of appearance, such as gloss and haze, and inexpensive appearance

measurement devices, such as glossmeters.

The standard specular gloss measurement defined by the American Society

for Testing and Materials (ASTM) in ASTM method D523 measures the

magnitude of light reflected in a small solid solid angle about the

specular direction. ASTM method E430 specifies that haze is a measure

of the fraction of light reflected in the off-specular direction to

that reflected in the specular direction. These well defined measurements

result in a single numerical value describing particular appearance

attributes of the measured surface. An analogous measurement may be

performed on the BRDF of a surface through computer simulation of

the measurement protocol. In this way, a simulated glossmeter or hazemeter

can be used to determine the gloss or haze of any arbitrary BRDF.

A computer program was developed which applies the measurement protocol

of many of these standardized appearance tools (eg., glossmeters and

hazemeters) to BRDFs. This new virtual light meter is essentially

a customized integration tool, using numerical quadrature of the specified

BRDF model over an adaptively subdivided source and receptor aperture

(see Figure 5 below) to compute the final standard appearance value.

In addition to being able to calculate the current standards, the

virtual light meter can be customized for other measurements. The

customizable parameters include the size and locations of the source

and receptor apertures, the specular angle, the surface orientation,

and the reflection model.

|

|

|

Figure 5: (left) Subdivision

of light meter apertures using the 60 degree specular gloss specifications.

The source and receptor apertures are oriented in directions  and

and  ,

60 degrees down from the surface normal, N, in the plane

of incidence. (right) Flux passing through receptor aperture due

to one source aperture subdivision. Aperture sizes are not to

scale. ,

60 degrees down from the surface normal, N, in the plane

of incidence. (right) Flux passing through receptor aperture due

to one source aperture subdivision. Aperture sizes are not to

scale. |

Standard gloss and haze values are directly dependent upon the measured

flux reflected off the surface and passing through the receptor aperture.

The integration of this flux begins by subdividing the source aperture.

For each sample point on the source, the receptor aperture is subdivided.

Based on the initial results of the integration, the receptor aperture

is adaptively subdivided until the discretely computed flux is within

some specified tolerance. Figure 5 above shows an example of the flux

due to one subdivided source element passing through the receptor.

After this flux is determined, the next source sample point is chosen

and the process is repeated. The source aperture continues to be subdivided

until a specified tolerance is achieved. Figures 6 and 7 are two renderings

of tiles with BRDF model parameters selected so as to achieve specific

gloss and haze values.

|

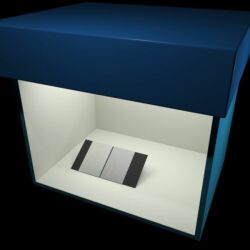

| Figure 6: Rendered tiles using BRDF

models with parameters set so as to produce 20 degree specular

gloss values 80, 60, 40, and 20. |

| |

|

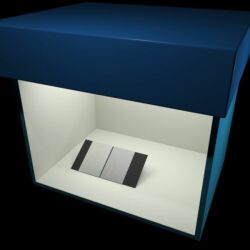

| Figure 7: Rendered tiles using BRDF

models with parameters set so as to produce 2 degree haze values

10, 60, 110, and 160.

|

|