|

Computer Graphic Rendering of Material Surfaces |

|

|

Computer Graphic Rendering of Material Surfaces |

|

Additional Images

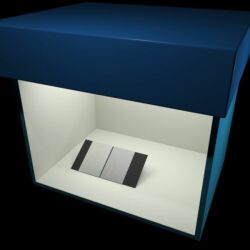

As discussed in the Light Meter section, standards exist for quantifying and measuring material appearance properties such as gloss and haze. Using these standards as a guide, we were able to render images of materials with specified appearance characteristics as shown in Figures 6 and 7.

A more recent appearance measurement, currently in the standardization process, is that used to characterize metallic paints and plastics. The method proposed for standardization specifies measurement of the tristimulus values at three angles. There is evidence that interpolation of three measured values can accurately characterize the appearance of metallic surfaces. A BRDF can then be generated from the interpolated tristimulus values and used with iBRDF to render synthetic images of objects modeled with metallic paint. Figure 16 below is an image of three vases modeled using tristimulus data measured from actual metallic paint samples and rendered using iBRDF. These vases demonstrate the sub-surface characteristic of metallic paint but not the usual glossiness attributed with metallic automobile finish. Combining the gonioapparent sub-surface reflection with a first-surface BRDF leads to a more realistic image as can be seen in Figure 17. The first-surface BRDF was chosen so that the 20 degree gloss values are 10 for the left shell and 60 for the right. More detail is provided in Westlund et al. [WESTL01].

Figure 16: Three vases with metallic paint but no clear coat Figure 17: Two automotive shells with 20 degree specular gloss of 10 and 60

|

Privacy Statement/Security Notice | Disclaimer | FOIA NIST is an agency of the U.S. Commerce Department's Technology Administration. |